Imagine a world where car repairs are less about banging out dents and more about reprogramming sensors and recalibrating lasers. Now imagine if I told you that this isn’t science fiction – it’s the future of panel beating, and it’s happening right now in Sydney.

As cars become more technologically advanced, repair methods are evolving too. This shift is being driven by new materials, electrification, autonomous driving systems, and even changes in consumer preferences.

The Rise of Electric Vehicles (EVs)

Electric vehicles are becoming increasingly popular, with sales in Australia surging by 65% in 2022. This shift presents new challenges for panel beaters. EVs come equipped with high-voltage batteries and intricate electrical systems, requiring specialised training and equipment for safe repairs.

Additionally, the lightweight materials used in EV construction, such as aluminium and carbon fibre, demand different repair techniques than traditional steel.

Advanced Driver-Assistance Systems (ADAS)

ADAS features, like lane departure warnings, automatic emergency braking, and adaptive cruise control, rely on a complex network of sensors, cameras, and radars. Even minor collisions can misalign these systems, making recalibration necessary after repairs. To ensure these safety features work correctly after an accident, panel beaters must invest in the latest diagnostic tools and training.

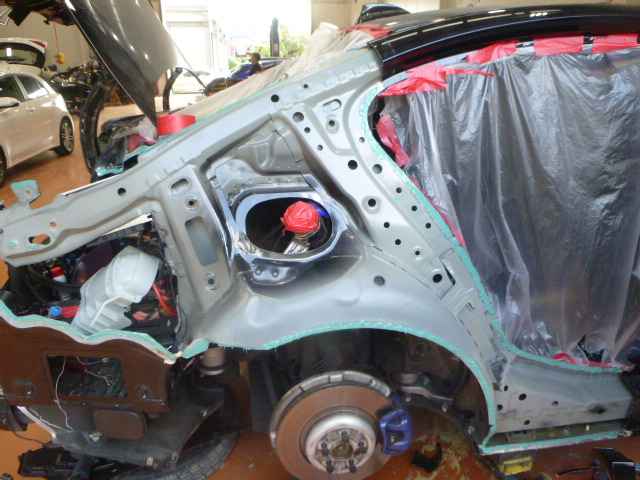

New Materials: High-tensile steel, Aluminium, and Carbon Fibre

Modern vehicles use a range of materials to enhance fuel efficiency and safety. High-tensile steel, which is stronger and lighter than traditional steel, is more challenging to repair. Aluminium and carbon fibre offer even greater weight savings but require specialised tools and techniques for repairs. To stay competitive, panel beaters need to invest in the equipment and training required to handle these advanced materials.

Fibre Optics and Connectivity

Modern cars are more connected than ever, with fibre optic networks transmitting data throughout the vehicle. Damage to these networks can disrupt critical systems, including infotainment and safety features. Repairing fibre optic cables requires precision and expertise, adding another layer of complexity to panel beating.

Matte Paint Finishes

Matte paint finishes are becoming more popular for their distinctive aesthetic, but they present unique challenges for refinishers. These finishes are more prone to scratches and require specialist techniques for blending and matching. Panel beaters must stay up-to-date with the latest paint technologies to ensure flawless repairs on vehicles with matte finishes.

Other Emerging Technologies

- 3D Printing: Though still in its early stages, 3D printing has the potential to transform the production of replacement parts, reducing both costs and lead times.

- Artificial Intelligence: AI-powered tools are enhancing damage assessment, estimating repair costs, and guiding technicians through complex repair processes.

- Virtual and Augmented Reality: VR and AR are being used for training, enabling technicians to practice repairs in a virtual environment before tackling real-world scenarios.

Embracing the Future

The future of panel beating is driven by constant technological advancements. To stay competitive, panel beaters must embrace innovation, continually invest in training, and adapt their techniques to handle new materials and sophisticated vehicle systems.

At Scientific Motor Body Works, understand the importance of staying ahead of the curve. Our focus in acquiring the latest equipment and providing ongoing training for our technicians means we are well-equipped to service the most advanced vehicles on the road today.

For drivers in Sydney’s Eastern Suburbs seeking panel-beating services that match the complexity of modern vehicles, SMBW is the clear choice.

Scientific Motor Body Works: Leading the Way in Sydney

In the rapidly evolving panel-beating industry, Scientific Motor Body Works (SMBW) sets the standard for excellence in Sydney. With factory certifications from 16 manufacturers, including Range Rover, BMW, Audi, Lexus, Volvo, and Jaguar, SMBW has the expertise to handle even the most complex repairs. No other panel beater in Australia boasts as many certifications, making SMBW a trusted choice for prestige vehicle repairs.

With our three convenient locations in Sydney CBD and the Eastern Suburbs, SMBW’s commitment to innovation is clear through our investment in advanced technology and ongoing technician training. From replacing carbon fibre panels on an Audi to recalibrating ADAS systems on a Tesla, SMBW ensures your vehicle is restored to its pre-accident condition with precision and care.

Contact us today to experience the future of panel beating. After all, shouldn’t your car’s repairs be as advanced as the car itself?